Any common milling machine, belt sander or saw can eventually remove a package lid, but rework-certifiable de-lid processes require much more precision and package protection.

For 30 years our de-lidder™ machines have been the industry's state of the art solution for removing lids from hermetic packages. Our systems are designed for cleanroom use, by cleanroom staff - not skilled machinists.

Our process uses special high-speed tooling, set up to machine through lid flanges from below. Particles are kept out of the package cavity by tool and lid geometry, gravity, and vacuum.

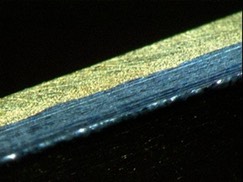

The photo at right shows a package wall after machining. The silvery side shows where a thin layer of nickel was melted between the package wall and lid flange. Our de-lidder™ machined through the lid flange right to this nickel, releasing the lid. The gold beside it surrounds the package cavity holding the circuit - note that the gold plating there is untouched - so it will hold the new lid at exactly the same height as the original.

During the reseal process, our machined surface tool marks help to spread nickel along the package wall, improving hermeticity - there is no need to sand the package after removing the lid, no extra cleaning.

Click on to our de-lidder™ information page for model history and links to brochures and data sheets.

Hi-Rel products have two characteristics that complicate component & die removal:

For many years, manufacturers simply limited rework temperatures to 150°C, intended to keep processes within thermal limits. The only problem was, this didn't work. Conductive epoxies designed to hold die onto circuit substrates took a long time to break down at 150°C, and in some cases just became tougher and tougher. So operators were left with one option- chipping away with chisels and screwdrivers while their products slowly baked.

In the mid 1980s, Midas Technology worked with AT&T Microelectronics on a new approach - HOT Gas Rework. This revolutionary approach used much higher temperatures delivered for a very short time to break down die attachments, without overheating adjacent devices. We introduced this process to industry in a series of high-powered machines, culminating in today's fifth-generation HGRS-V.

Click on to our HGRS Information Page for model history and links to brochures and data sheets.