Countless types of electronic products are made, but most share one thing - they are designed to be made in huge volumes, easily and at lowest cost.

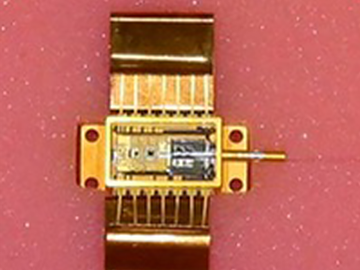

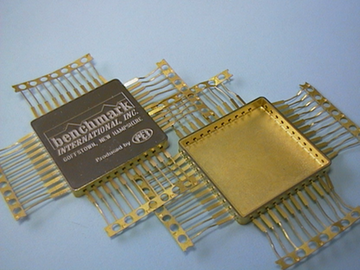

"Hi-Rel" or High Reliability products are different. They are made for aerospace, defense, telecommunications networks, MEMS (microelectromechanical systems) and implanted medical applications where performance and longevity are more important than price. Their manufacture involves complex assemblies with large numbers of connections packed into the smallest possible space, along with exhaustive testing and documentation. Often they are hermetically sealed in gold-plated metal cases (such as the demo versions at right) filled with non-corrosive nitrogen gas. All this makes Hi-Rel products too costly to scrap.

Midas Technology provides the key technologies that allow Hi-Rel manufacturers to safely and properly rework their products. Click Markets to learn how different customer types use our technology.

Defective Hi-Rel circuits (such as aerospace hybrids, MEMs, optical devices and other complex microcircuits) can't legally be repaired, but they are expensive to scrap. "Rework" uses proven, qualified processes to rebuild circuits into their original, as-new condition. This saves critical time and money that would be required to replace them.

Restoring a defective hi-rel microelectronic circuit to its original specifications - in function and physical condition - is termed "Rework". This can be difficult, because packaged microelectronics are complex and subject to many manufacturing restrictions. In many cases, they are not designed to be reworked.

Rework is NOT the same as repair, which restores function but may change physical specifications. So why not just repair defective parts?

Because it is not allowed. Many high reliability applications prohibit repaired parts, because it is not possible to confirm they will meet performance and durability limits. Genuine "rework" promises parts that are good as new.

This is where Midas Technology comes in. Our machines allow manufacturers to accomplish two tasks that are critical to successful rework: Remove Lids & Remove Die